Loading...

Loading...

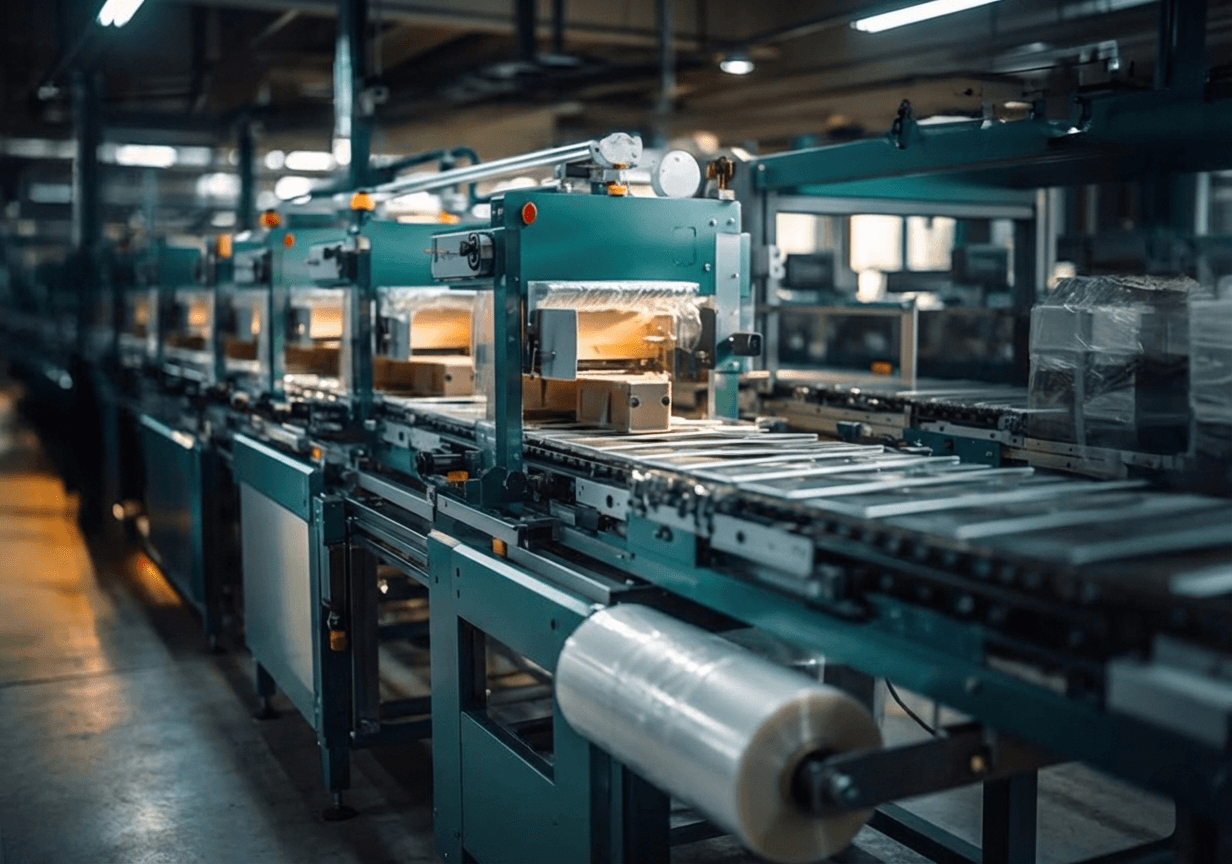

Industrial automation has revolutionized the manufacturing sector, driving unprecedented efficiency, scalability, and productivity. By integrating advanced technologies and intelligent systems, automation empowers industries to meet evolving demands, maintain competitiveness, and address modern challenges. In this blog, we explore how industrial automation enhances manufacturing processes, the services and segments it impacts, and how an automation solution provider can serve as a one-stop partner for transforming manufacturing facilities.

In today’s fast-paced and competitive market, the manufacturing industry faces several challenges, such as Rising operational costs, Demand for Quality, Global competition, Labor shortages, and Environmental Compliance.

Industrial automation addresses these issues by offering scalable and efficient solutions that reduce human intervention, minimize errors, and enhance production capacity. Omron Proximity Sensors and Industrial Panel PCs offer solutions to streamline processes and minimize human intervention.

♢ Process Automation: Our automation streamlines repetitive tasks, such as assembly, welding, and packaging, ensuring precision and speed. Explore our Industrial Panel PC solutions for seamless integration.

♢ Robotics Integration: Robots enhance productivity in areas like material handling, machine tending, and quality inspection. Collaborative robots (cobots) work alongside human operators, increasing flexibility and safety. Learn more about our Omron Robotics .

♢ Control Systems: We offer advanced control systems, like Programmable Logic Controllers (PLCs) and Distributed Control Systems (DCS), that provides real-time monitoring and adjustments, optimizing processes and minimizing downtime.

♢ Industrial IoT (IIoT) Solutions: Our Advance IIoT connects devices and sensors across the manufacturing floor, enabling data-driven decision-making and predictive maintenance.

♢ Energy Management: Automation systems monitor and optimize energy usage, reducing costs and supporting sustainability goals. Reduce costs with our advanced Energy Efficient Solutions.

♢ Safety Systems: Our automation solution integrates safety protocols, such as emergency shutdowns and hazard detection, protecting both workers and equipment.

♢ Higher Throughput: Automated systems operate continuously, significantly increasing production output.

♢ Improved Quality: Automation ensures consistent quality by reducing human error and adhering to precise standards.

♢ Cost Reduction: By minimizing waste, downtime, and labor costs, automation improves overall profitability.

♢ Faster Time-to-Market: Streamlined operations enable manufacturers to respond swiftly to market demands.

♢ Data-Driven Insights: Real-time data analytics help identify inefficiencies, predict maintenance needs, and optimize processes.

Automation solution providers play a critical role in transforming manufacturing facilities.

They offer:

♢ Comprehensive Assessment: Providers evaluate current systems, identify bottlenecks, and recommend tailored automation strategies.

♢ Custom Solutions: From robotics to software integration, solution providers design and implement systems that align with specific manufacturing needs.

♢ One-Stop Integration: They deliver end-to-end solutions, combining hardware, software, and maintenance into a seamless package.

♢ Training and Support: Providers offer training programs and ongoing support, ensuring smooth transitions and optimal use of automated systems.

♢ Scalability and Future-Readiness: Solutions are designed to grow with the business and adapt to future technological advancements.

Industrial automation is no longer a luxury but a necessity for manufacturers striving to stay competitive in a rapidly evolving landscape. By embracing automation, industries can enhance efficiency, reduce costs, and achieve sustainable growth. Partnering with Lubi Electronics as an automation solution provider ensures a streamlined transition, tailored solutions, and ongoing support to overcome challenges and unlock the full potential of automated manufacturing. Discover the potential of our Omron Temperature Controllers and Industrial Panel PCs today.

Every day in your plant, people, machines, and materials move continuously. Your teams focus on meeting production targets, maintaining quality, and keeping operations running smoothly. At the same time, safety and uptime remain constant concerns...

Computer vision and CCTV technologies are reshaping modern factories by enabling real-time monitoring, intelligent decision-making, and enhanced safety, allowing manufacturing systems to “see,” analyze, and respond with greater accuracy and efficiency.

An overhead conveyor or transfer system is an elevated system that is used to transport items throughout the facility. In an Overhead Transfer System (OTS) the trolleys that hold the item are generally rings or hooks.